|

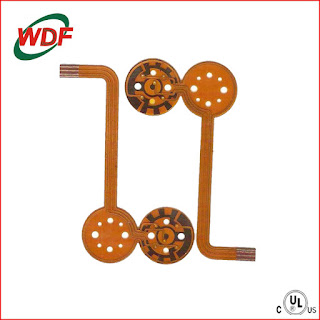

| Flexible PCB( WDF-FPC-D-18 ) - wonderfulpcb.com |

A famous star need a good director, if Jack Chen or Tom Hanks, or Nicolas Cage met with a mediocre director, I guess the box office would take a tumble.

Just like to find a good director for a movie, if you are purchasing for PCB circuit boards, you need to find a good PCB supplier firstly.

Here are some proven tips to guide you through the selection process successfully.

Market Orientation:

Carrying out a background research on the different suppliers will help you know the exact price that you should pay for the services to be rendered. Understanding market orientation can also help you find quality services. Note that each PCB supplier specializes in one field that he or she is good at.

Manufacturing criteria:

What is cared most often is the manufacturing criteria of PCB supplier, his/her production capacity, lead-time, quality, and service. If a PCB supplier only have a low production capacity, your purchasing requirements may not be satisfied, for example, you need to produce a multilayer board while technology and devices of the supplier are backward and couldn’t take this order. Punctual lead-time is one of points to be considered, it is related with production capacity but also related with management system of the PCB supplier. A superior management system will greatly improve production efficiency. At last, a good service also is essential which includes prompt reply, good communication, and settlements for the quality issues.

Desist from choosing PCB suppliers who offer low prices. Instead, you should find suppliers whose prices are directly proportional to the quality of the products. Sometimes, low quality products are very cheap as compared to high quality products. One of the major benefits of purchasing a high quality product is that they are more cost effective since they are more durable hence they require less repair or maintenance services.

Finally, find companies that have a clean track record so as to get value for your money. Their repairing costs should be affordable and in line with your budget. Once your products have passed the R & D, find a reliable partner who can help you establish and expand your market and credibility.

A PCB supplier in Shenzhen of China which you must be interested in:

http://www.wonderfulpcb.com